Process: 3D Scanning

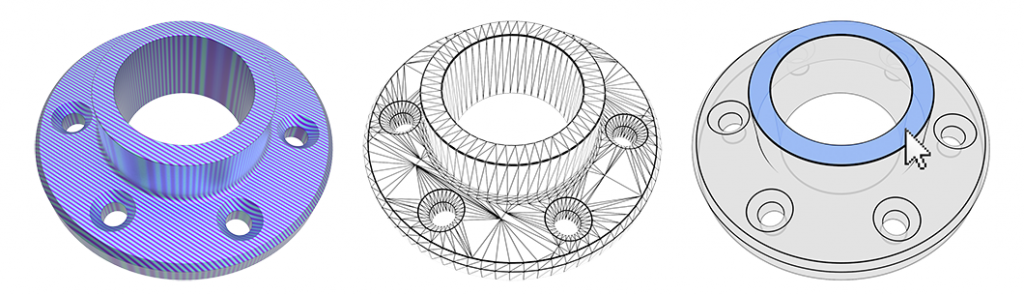

The process we use is Blue Light Scanning which projects a pattern of light onto the surface and cameras are used to measure the deflection of the pattern and capture the geometry. This process produces a “point cloud” which can be joined into a triangulated mesh. This mesh file, also called an STL file can be used for rapid prototyping such as 3D printing and 3D rendering. Apart from scaling, mirroring and other basic operations, STLs cannot be easily modified or generally used for other manufacturing processes.

If the scan data is required for tooling, mould making, recreating 2D drawings or importing into CAD software as a basis for designs it must be reverse engineered to surface data (typically STEP/IGES) and imported into a CAD package such as Solidworks or AutoCAD. This is a design process whereby a CAD model is constructed in a traditional way using points from the imported mesh as a reference to build the new model.

Machine: Artec Space Spider

A new and enhanced precision instrument for CAD users and engineers, Artec Space Spider is a high-resolution 3D scanner based on blue light technology. It is perfect for capturing small objects or intricate details of large industrial objects in high resolution, with steadfast accuracy and brilliant color.

The scanner’s ability to render complex geometry, sharp edges and thin ribs sets our technology apart. It is an ideal industrial 3D scanner for high resolution capturing of objects such as molding parts, PCBs, keys, coins or even a human ear, followed by the export of the final 3D model to CAD software.

Space Spider offers almost unlimited possibilities in areas such as reverse engineering, quality control, product design and manufacturing.

3D point accuracy: 0.05 mm

3D resolution: 0.1 mm

Texture resolution: 1.3 Mpx

3D Scanning: Applications

- Archaeological artefacts

- Reverse engineering products

- Measurement and analysis

- Recreating lost CAD data

- Body scanning

- Sculpture and casting

- Props for TV and film

- Archiving museum pieces

- Scaling and replicating objects

Considerations: 3D Scanning

Transparent or reflective surfaces can only be scanned with application of water-soluble spray.

Regions behind transparent surfaces cannot be scanned.

Internal, fully enclosed or otherwise obscured or inaccessible geometry cannot be scanned.

Deep, narrow cavities cannot be scanned (i.e. inside of screw bosses etc).

Objects larger than 50cm can be scanned at additional time and cost and at the discretion of ProtoUK.